Introduction

Workplace safety isn’t just about reacting to incidents it’s about preventing them. One of the most effective tools used by safety professionals to identify root causes of incidents is the 5 Whys technique. Despite its simplicity, the 5 Whys method offers deep insights that help organizations go beyond surface-level fixes and implement meaningful, long-term solutions.

In this blog, we’ll dive into what the 5 Whys technique is, how it’s applied in safety management, and why it should be a key part of your root cause analysis toolkit.

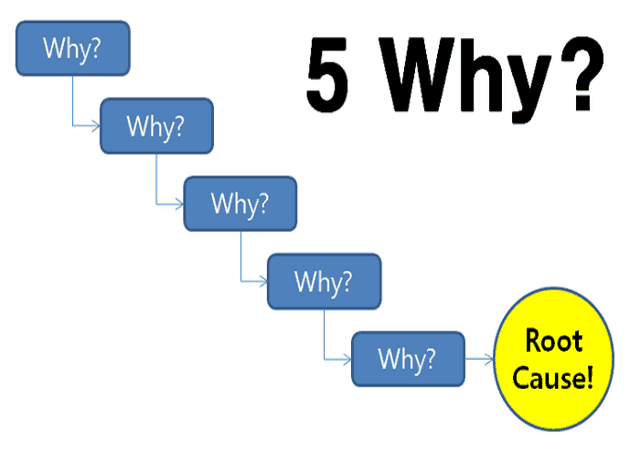

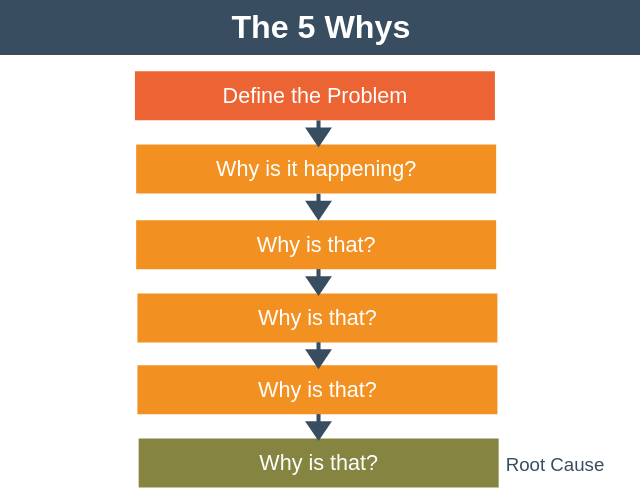

What is the 5 Whys Technique?

The 5 Whys Technique is a root cause analysis method that involves asking the question “Why?” repeatedly (typically five times) to explore the underlying cause of a problem. It was originally developed by Sakichi Toyoda, the founder of Toyota Industries, and later became a core part of the Toyota Production System.

In the context of safety, the 5 Whys helps investigators move past symptoms and identify systemic or behavioral causes of incidents.

Why Use the 5 Whys in Safety?

- To understand the real cause behind near misses, incidents, or unsafe behavior

- To avoid superficial or incomplete solutions

- To prevent recurrence of similar events

- To encourage a culture of continuous improvement

- To engage teams in safety investigations with a simple, structured method

How to Perform the 5 Whys Analysis (Step-by-Step)

Step 1: Define the Problem Clearly

Write a concise problem statement.

Example: “Worker slipped on the shop floor.”

Step 2: Ask “Why?”

Start with the problem and ask why it happened.

Step 3: Repeat “Why?”

Use each answer as the basis for the next question. Repeat at least five times or until the root cause is uncovered.

Step 4: Identify the Root Cause

When asking “Why?” no longer produces a useful response, you’ve likely reached the root cause.

Step 5: Take Corrective Action

Develop and implement actions that address the root cause — not just the symptom.

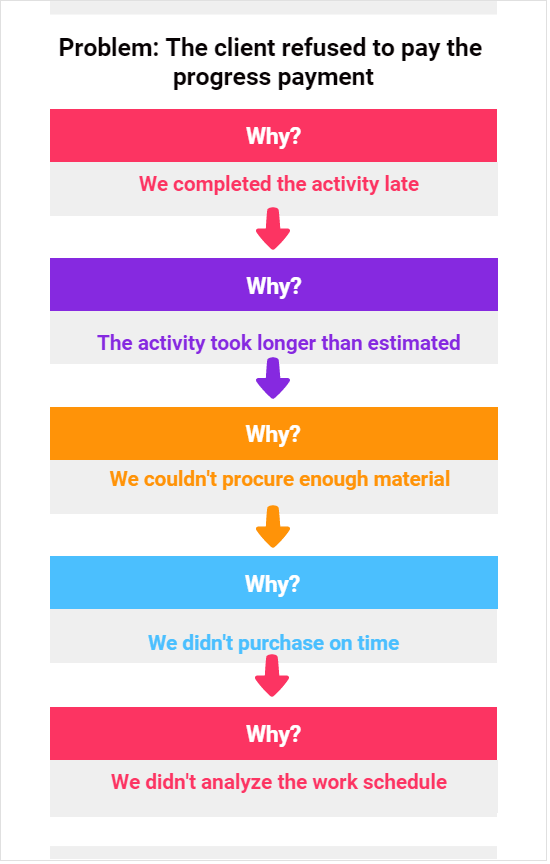

Example of 5 Whys in Safety

Problem: A worker slipped and fell in the warehouse.

- Why did the worker slip?

Because the floor was wet. - Why was the floor wet?

Because a water pipe was leaking. - Why was the pipe leaking?

Because it had not been maintained properly. - Why was it not maintained?

Because there is no regular maintenance schedule. - Why is there no schedule?

Because the safety procedures don’t include preventive maintenance planning.

Root Cause: Lack of preventive maintenance planning in safety procedures.

Action: Update safety SOPs to include a maintenance schedule and regular inspections.

Tips for Using 5 Whys Effectively

- Involve the right people: Include workers, supervisors, and safety officers who understand the situation.

- Don’t stop too early: Dig deep — sometimes more than five whys are needed.

- Avoid blaming individuals: Focus on systems, processes, and organizational issues.

- Document each step: Keep a clear record for audits, reports, and future learning.

- Pair with other tools: Use alongside techniques like FTA or FMEA for more complex issues.

Advantages of the 5 Whys Technique

- Simple and quick to perform

- No technical tools required

- Encourages team collaboration

- Promotes critical thinking

- Works well for both small and large incidents

Limitations to Be Aware Of

- May lead to subjective answers if not facilitated well

- Can oversimplify complex problems

- Depends on the investigator’s skill and mindset

- Not ideal for multi-root or interrelated causes without additional tools

When to Use the 5 Whys in Safety

- After near-miss reports

- Following first-aid cases or minor injuries

- During safety audits or hazard observations

- For behavioral safety concerns

- As part of continuous improvement in your safety management system

Conclusion

The 5 Whys technique may seem simple, but when used correctly, it is a powerful problem-solving tool in safety. It helps uncover the true causes of incidents, improve safety systems, and foster a culture of accountability and prevention. Start using the 5 Whys today to make your workplace safer, smarter, and more resilient.