How a Fire Alarm System Saved a Manufacturing Plant from a Major Disaster

In industrial environments, the risk of fire is ever-present. Manufacturing plants, due to their machinery, electrical loads, chemical storage, and continuous operations, are highly vulnerable to fire-related emergencies. One incident can lead to loss of life, major financial damage, and even long-term shutdown. Fortunately, in this case, a fire alarm system prevented such a disaster and proved why having a robust and functional alarm system is not just important but absolutely critical.

This real-life event from an electrical components manufacturing plant highlights the lifesaving impact a fire alarm system can have, especially when installed and maintained correctly.

The Incident: A Normal Night Shift Turned Risky

It was an ordinary Thursday night. The night shift at a mid-sized electrical manufacturing plant in Lahore was running smoothly. Operators were assembling printed circuit boards while forklifts moved materials across the shop floor. Unbeknownst to anyone, a short circuit was developing inside one of the storage racks that held plastic casing materials.

Within minutes, the cable insulation failed, and heat started building up. The material began to smolder slowly, releasing smoke not yet visible to any staff members.

The Role of the Fire Alarm System

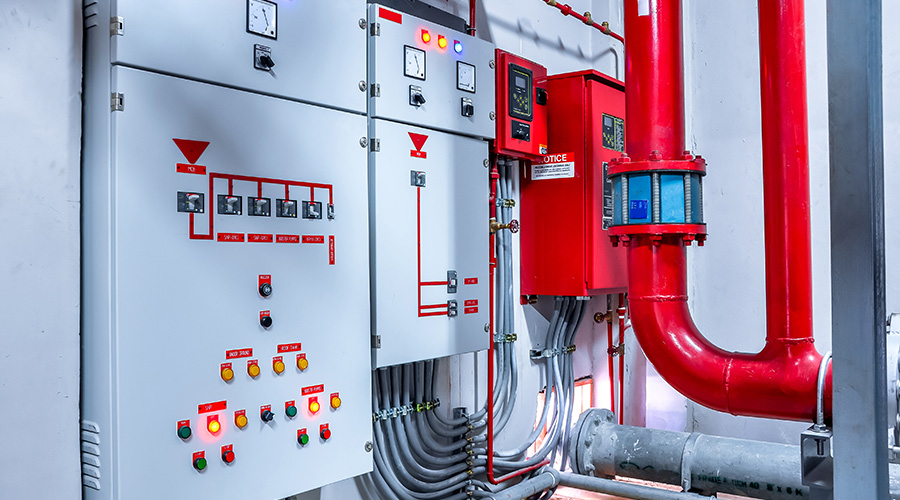

Installed across all zones of the plant was a state-of-the-art fire alarm system, consisting of smoke detectors, heat sensors, and centralized control panels.

As soon as smoke levels crossed the threshold in that storage section, the fire alarm system immediately activated. The alarm triggered a loud audible signal, strobe lights flashed across all production zones, and an automated voice alert instructed employees to evacuate calmly.

The plant’s security control room received a real-time notification from the fire alarm control panel, including the exact location of the triggered detector.

Rapid Response and Containment

Thanks to the immediate warning by the fire alarm system, the on-site emergency team reached the storage area within 90 seconds. They identified the source of smoke—a smoldering cable beneath stacked plastic containers. Fire extinguishers were used to control the fire before it could spread.

Simultaneously, the local fire department, already notified by the system’s external communication module, arrived at the site in less than 6 minutes. The situation was fully controlled without any injuries, property loss, or production downtime.

Why This Fire Alarm System Was a Success

- Early Detection – The smoke detectors sensed the fire before it became visible or dangerous.

- Zoned Alerts – The system was configured by location, enabling precise and quick response.

- Automated Communication – It informed the emergency team and fire services without manual input.

- Employee Safety – Staff were evacuated before any health risk emerged.

- Minimal Damage – No equipment or stock was damaged due to timely suppression.

Lessons Learned: Why Every Plant Needs a Fire Alarm System

This incident reinforced the critical role a fire alarm system plays in industrial safety. If the alarm had failed or not existed, the fire could have rapidly spread to nearby flammable materials, resulting in a catastrophic blaze. Potential outcomes could have included:

- Complete destruction of raw materials

- Machinery damage worth millions

- Production delays

- Legal and regulatory consequences

- Employee injuries or fatalities

It is often said that safety systems are unnoticed until they are needed. This story proves that investing in a reliable fire alarm system is not just a compliance step—it’s a business-saving, life-saving decision.

Key Features of an Effective Fire Alarm System in Manufacturing

To replicate this success, industries should ensure that their fire alarm systems have:

- Zoned coverage

- Smoke, heat, and flame detectors

- Real-time monitoring and remote alerting

- Integration with suppression systems

- Regular inspection and maintenance protocols

A fire alarm system is not just about installing a few detectors. It is a complete network of smart, responsive technology working to protect life and infrastructure.

Final Thoughts

The plant’s survival and safety of its people were made possible by one element an effective fire alarm system. In today’s high-risk industrial environments, there is no room for delay, no tolerance for malfunction, and no excuse for compromise when it comes to fire detection.

Business owners, plant managers, and facility supervisors must take this as a wake-up call. If your facility lacks a modern, reliable fire alarm system, the question is not “if” an emergency will happen—but whether you’ll be ready when it does.